What Are Railway Measurement Runs?

Railway transport is one of the safest means of transportation in Europe due to the fact that it undergoes rigorous testing and strict criteria. Railway measurement runs involve collecting and analysing data during the actual operation of rail vehicles. These runs measure critical parameters such as the forces between the wheel and rail, accelerations in the suspension stages, and relative distances of moving components.

At Applus+ Laboratories, we utilise our expertise to execute measurement runs and long-term measurements, providing a comprehensive understanding of the stresses experienced by rail vehicles. This information is essential for assessing the impact on service life, verifying operational strength, and optimising structures to prevent potential issues.

Why is Railway Measurement Runs Important?

Railway measurement runs are crucial for maintaining the safety, reliability, and efficiency of rail transport. By understanding the stresses and conditions experienced by rail vehicles, operators can:

- Assess the impact on service life

- Verify operational strength

- Optimise structures to prevent issues before they arise

What Railway Measurement Runs Do We Provide?

We offer an extensive range of measurement services designed to address various needs within the railway industry. Our services include:

- Approval & validation measurements

- Damage case analysis

- Running characteristics technical & load collective measurements

- Force measurements

- Measuring wheelsets

- Measuring brake systems

- Torsional vibration measurements

- Assuming railway operational services for measurement runs

- Modal analysis and operating vibration analysis

- Measuring railway noise and vibrations

- Electrical measurements

- Pantograph measurements

- Structure monitoring

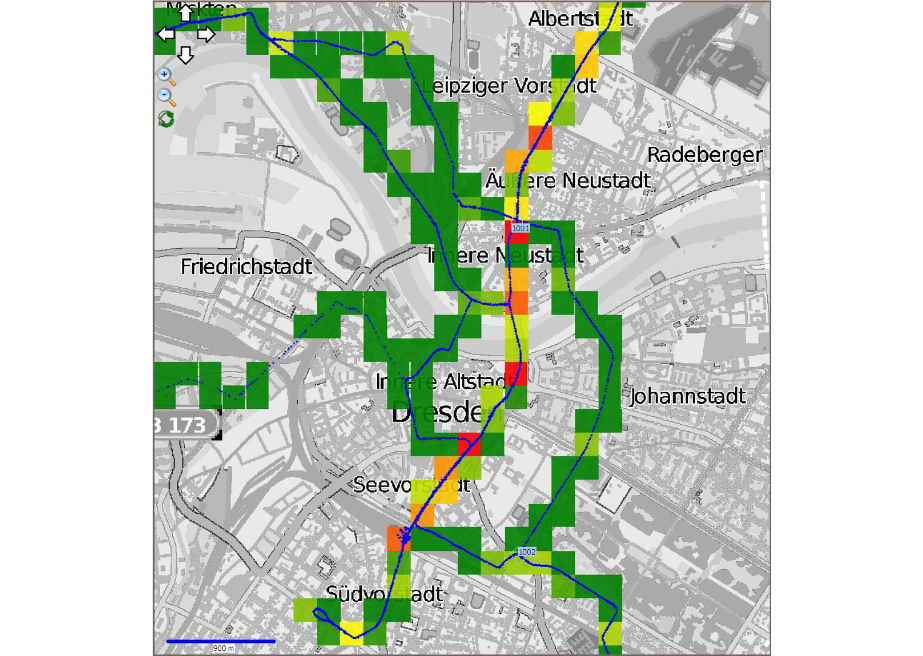

Example of a damage map

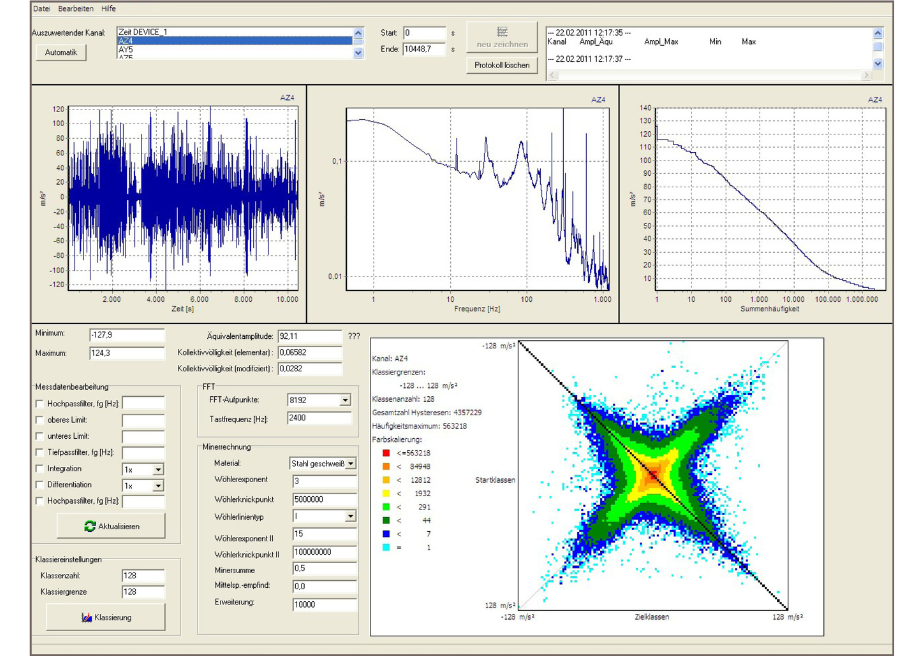

Evaluation of a measurement run

Evaluation of a measurement run

Stress Measurement and Test Drives

Our stress measurement and test drives capture the stresses that rail vehicles experience under actual operating conditions. Through continuous monitoring, we record mechanical and electrical variables under static and dynamic loads. This includes installing complete measurement chains, including process adaptation, to ensure accurate data collection. We create load assumptions that serve as the basis for calculations using the finite element method (FEM) and various in-house tests.

Whether operating in Helsinki, Melbourne, or Dresden, our on-site measuring service offers extensive capabilities with high channel counts and sampling rates, accommodating harsh environmental conditions and autonomous measurements in regular use. We execute tests in accordance with the application guidelines for distance and route trials in the rail vehicle sector, according to the standards DIN EN 13749 and VDV 152, and with data evaluations according to EN 17149 and the FKM-Guideline.

Long-Term Measurements

We support long-term measurements for data acquisition during actual operation, which are crucial for assessing the impact on service life and verifying operational strength. Our systems can monitor structures, components, systems, and plants tailored to your specific requirements, immediately and reliably informing you of any load or damage incidents.

Analogue signals such as strain gauges, accelerations, and displacements are measured by us in conjunction with GPS and bus data in numerous applications across various fields. This extensive data collection enables detailed assessments, including location-based evaluations of measurement data over several years.

Modern Measuring Systems

Our modern measuring systems utilise digital measurement technology and a variety of transducer types to collect, record, and process both static and dynamic parameters. These parameters include:

- Force & torque

- Displacement

- Pressure, elongation & strain

- Speed & acceleration

- Relative air humidity

We register elongation and strain using two methods: firstly, with strain gauges, and secondly with optical measurements via our ARAMIS system, capable of measuring in-plane and out-of-plane deformations. For rapid processes, such as free-fall trials, we employ high-speed cameras.

We utilise our own software solutions to visualise data in real time, including rainflow counting and envelope calculations according to additional algorithms. In addition, we deploy telemetry systems to collect and record measurement data from rotating components, ensuring comprehensive data acquisition across various scenarios.

Why Choose Applus+ Laboratories for Railway Measurement Runs?

Choosing Applus+ Laboratories for your railway measurement runs means partnering with a distinguished leader in the railway testing industry. Our many years of experience guarantee effective solutions for status, condition, and load analysis. We offer more than just the execution of measurement runs.

We are committed to ensuring that your rail vehicles are safe, reliable, and compliant with global regulations and standards. By choosing Applus+ Laboratories, you gain access to advanced testing facilities, cutting-edge equipment, and a team of experts dedicated to delivering high-quality services and expert guidance.